SPC - Statistical Process Control

Module Guide - A Deeper Dive!

Introduction

V5 Traceability features a module designed for quality assurance professionals to assist them in recording SPC (Statistical Process Control) sample data.

Often, the sample data requirements are focused primarily on weight data, ensuring packs are maintaining a standard weight, with a tolerable Standard Deviation. Other physical attributes (length, width, height, color, odor etc) can be captured to control the proces further.

In addition to capturing manual offline samples data, V5 Traceability can be setup to import data from dynamic checkweighers. This provides visibility on 100% of production which improves accuracy.

Results can be generated in reports. This module guide will look at how to set these up and how they are undertaken.

Table of Contents

1. SPC Setup

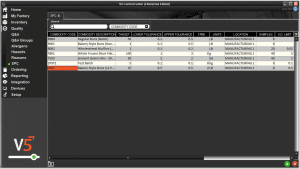

To schedule a SPC run for a Terminal operator we first need to create it in Control Center. We can do this by heading to the SPC window (Quality -> SPC), and adding a new line via the green ‘+’ in the bottom right of the window.

Once this new line is added, we can select our commodity to be tested, either by typing into the ‘Commodity Code’ cell, or by selecting from the drop-down menu.

Once this is done, we can then populate the cells for our desired target weight, tolerances, standard deviation (SD) limit etc. For assistance with the various column settings and definitions click here.

Having now set up an SPC run for ‘Bakery Style Buns (12 Pack), this will now display for a Terminal operator to select.

2. Using SPC In Terminal

The SPC run will now be visible to the Terminal operator, and will begin once they select the Bakery Style Buns and hits the green check mark.

The operator will then be asked any questions that have been assigned to the ‘SPC Start’ event before proceeding to the run itself.

Note how the operator is not asked to scan a lot for the product, allowing the subject of SPC runs to be selected at random from existing stock. Of course, if it is desirable to know what lot is being tested then this can be asked as a pre-run question as indicated above.

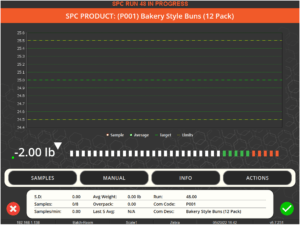

Also note how the scale is set at -2lbs, which was our ‘Tare’ value from the Control Center setup, and in this case is taking account of the buns’ packaging.

We can then begin to weigh our samples.

As we go, the Terminal display will visually represent the individual and average weights, as well as how many more samples we have to weigh, how many samples per minute we are weighing, current Standard Deviation of the current sample set etc.

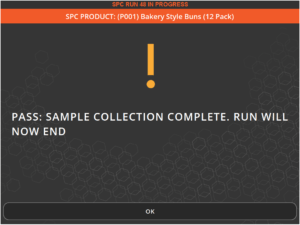

Once the run has been completed, and if all our samples have passed the standard deviation limits, then the run will pass.

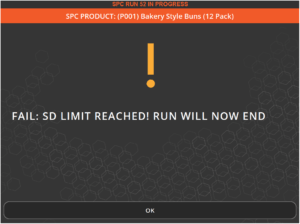

However, if our samples exceed the standard deviation limits, then the run will fail.

3. SPC Reports

We can use 3 reports to retrieve SPC information from the system. These are: