Hazards

Module Guide - A Deeper Dive!

Introduction

When coming into close contact with hazardous materials or environments, it is mandated by law that companies follow correct hazard and safety protocols and record that they are doing so.

V5 Traceability makes this process very simple, streamlined, and digital. Each time hazardous materials are handled; operators are warned with relevant GHS Symbols and language translatable warning text. Operators’ confirmation is always required, and V5 Traceability logs the responses for audit purposes.

The Harard module is very simple to setup with little to no configuration required.

This module guide will present instructions of how to do this, as well as taking a look at how this would look to a Terminal operator once setup has been completed.

Table of Contents

1. Hazards Setup

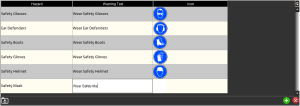

V5 Control Center comes pre packaged with a selection of common hazards for easy setup, but we can add to this by creating our own.

To set up a Hazard we first need to create a new entry in the top panel. This can be done by hitting the green ‘+’ in the bottom right of this panel. This will then create a new entry. The first 2 columns are both freetext and allow customers to define the Hazard, as well as the text that will be displayed to an operator when this Hazard is triggered. In this case, we will create a Hazard that will tell operators to wear a safety mask.

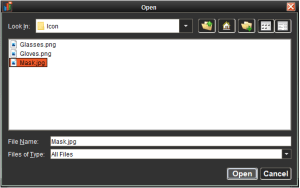

Clicking within the ‘Icon’ column will open a file import window. This allows for custom images to imported and assigned to a Hazard. Navigate to the directory of the icon, select the desired file and select ‘open’ to bring it in to the Control Center. All images will be scaled down to 50×50. This is to enable them to be displayed appropriately on the Terminal displays.

As we can see our setup of the Hazard is now complete. We can now move on to defining what will trigger this to be displayed.

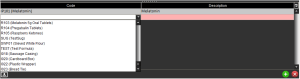

With our new selected in the top panel, we can use the ‘+’ button in the bottom panel to add commodities. These can be individual ingredients, packaging, formulas, or products.

Hazard setup is now complete. If these commodities are then handled during batch or product production, then the system will display the Hazard’s icon and assosciated warning text to the operator.

2. Hazards & Formula Production

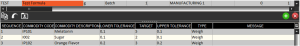

As we saw above, Hazards can be setup to relate to the handling of particular commodities. This means that during a production run that features the selected commodities, the relevant hazard message will be displayed. We can see this if we schedule a production run of a formula that includes melatonin.

When an operator then comes to produce a batch of this in Terminal, the system will display the ‘Wear Safety Mask’ hazard message.

Terminal can be configured to display the Hazard message at different, or multiple, points during production. The default is for the Hazard to be displayed at the start of a run featuring a hazardous commodity. This can be changed so that the Hazard is displayed only on the step of the formula that uses that specific commodity. This is useful for formulas which may contain several hazardous commodities. There is also the option for the system to do both. This can be useful if a second warning is required/advisable for more hazardous materials.

Please contact SG support for help setting this up.