Reasons

Module Guide - A Deeper Dive!

Introduction

When situations happen in manufacturing, there is almost always a need to record a reason for the nature of the occurrence. This normally takes place in response to auditor requiring satisfactory explanations to everyday issues.

V5 Traceability allows management to enter a list of the most common reasons to assist operators in entering timely responses for things such as ‘damaged bags’, ‘contaminated ingredients’, ‘line stoppage; etc.

Reasons can be setup within V5 Traceability to assist Operators recording correct information and limit data entry issues and mistakes.

Different reasons can be captured in different scenarios, all configurable within the system as standard. This module guide allows users to understand the setup and configuration of all Reason codes within the product.

Table of Contents

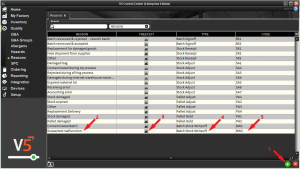

1. Reasons Setup

The first step to setting up a Reason within Control Center is to hit the green ‘+’ (1) in the bottom right of the main panel. This will create a new entry on the list. A Reason can then be entered in the first column (2). This will be the text that the operator will be presented with when they undertake the action defined in ‘type’ (see below). Multiple different reasons can be provided for each ‘type’ of action. This allows operators to choose the Reason which best explains their actions.

Ticking the ‘freetext’ box (3) will allow the operator to add further information if they choose this reason. This is useful for providing managers and supervisors with additional information on why an action was performed.

The final column (5 – ‘code’) allows alphanumeric input for a code of the customer’s choosing. This can be shorthand for a particular Reason, and is useful when generating reports.

Finally, we need to define the ‘type’ (4) for our Reason. This defines when V5 Traceability will ask operators to provide reasons for their actions.

2. The ‘Types’

As mentioned above, the ‘Type’ we assign to our created reason will dictate when a reason is prompted for. We have several options in this regard, which will be defined below.

Selecting all will ask the operator to provide a Reason for their actions under all of the circumstances outlined below.

Sets the Reason to an ‘Approval’ type, for use when approving checklists/formula changes etc.

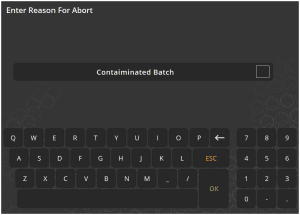

Prompts for a reason on the production Terminal when a batch is aborted.

Prompts for a reason when adding or editing batches in the ‘Batch View‘ window in Control Center.

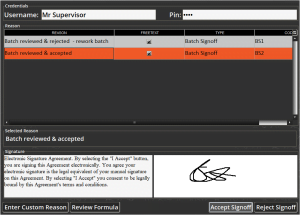

This event occurs after the completion of batch production. This must be enabled, and can be done so by making sure the ‘signoff required’ box is checked for that particular batch’s formula under the ‘Formulas’ section of Control Center. This feature can also be enabled globally if required for every production run. Please contact SG support for help setting this up.

During batch processing on the Terminal application, on completion of a sample batch, the operator will be presented with the following screen in Terminal.

This will then require a supervisor or manager to input their V5 credentials at the top. As we can see we have ‘Mr Supervisor’ on hand to do this. The supervisor will then have to check and sign off on the batch in question. In this instance the batch is perfectly fine and so Mr Supervisor will choose ‘Batch reviewed & accepted’, provide an electronic signature, and select ‘Accept Signoff’. This will then allow the batch to be completed and a label will be printed as normal.

If, for whatever reason, the batch isn’t acceptable, then the supervisor would select the ‘Batch reviewed & rejected – rework batch’ and select ‘Reject Signoff’.

If the supervisor wishes to provide additional details, this can be done via the ‘Enter Custom Reason’ before accepting or rejecting signoff.

In order for a supervisor to be able to accept a batch’s signoff, they must be granted this privilege. This can be granted under the ‘Operators’ section of Control Center by checking ‘Sign Off Batches’ under the ‘Terminal’ section of ‘Privileges’ (see ‘Operators’ guide).

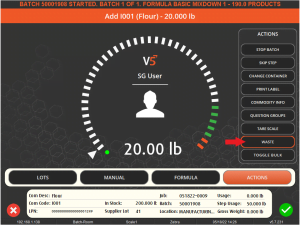

The stock write-off function is featured in the Terminal software, and allows operators to ‘waste’ specific amounts of commodities used during batching. This can be accessed by the operator by pressing the ‘actions’ button while undertaking batch production.

They will then be prompted to input the weight of the commodity from the current lot to be written off. Following confirmation of the weight to be written off, our list of Reasons will be displayed for the operator to choose from. This is useful if an amount of an ingredient is spilled during batching and managers need to be made aware that this has been written off.

Following confirmation, the specified amount of that commodity will be removed from the lot.

Batch Stock Writeoff is not enabled as standard within Terminal. If this feature is required, please contact SG support for help enabling it.

Prompts for a reason whenever a formula is edited in Control Center. It is required that the operator has the ‘Edit Formulas’ privilege.

This works in a similar way to ‘Stock Adjust’ above, but applies when changing stock levels on a particular pallet in WMS. If we access a particular pallet via WMS’s pallet manager and attempt to change an item’s stock level on a pallet, then we will be asked to provide a Reason for this.

Sometimes it is required to hold a pallet until further action can be taken. This can be done at the end of a purchase order if there is an issue with a delivered pallet, or via WMS’s pallet manager. As with adjustments, if we select a pallet and create a new hold on it, then we will be presented with our predefined Reasons to choose from.

Prompts for a reason when a QA event signoff is used. These can be set to single or double signoff.

Prompts for a reason whenever the ‘Scale Only‘ mode is activated on a production Terminal.

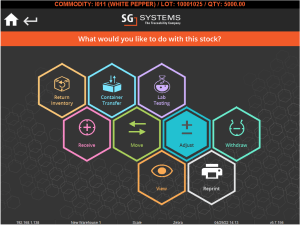

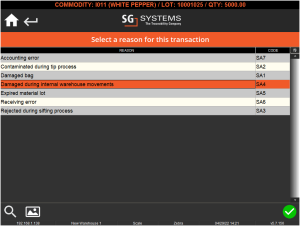

These Reasons will be displayed in WMS to an operator when they attempt to change stock levels for a particular commodity. Let’s use an example below of 5000lbs of white pepper.

Let’s then say that 1000lbs of this stock was damaged during transport in the warehouse. The operator would remove this damaged stock and weigh in the rest to be the new stock level. Once this new weight is entered in the system, our Reasons for this will be presented.

In this case, we will obviously choose ‘Damaged during internal warehouse movements’.

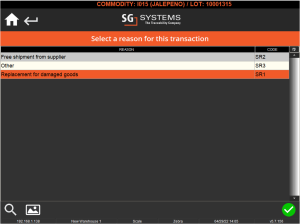

This event is trigged when commodities are brought into stock outside of the Purchase Order process. This allows operators in WMS to provide reasons to management for why a particular shipment has arrived outside of this system.

In the example below, we can attempt to add new stock for a commodity via the WMS ‘Commodities’ screen. Upon doing so, we are presented with the reasons we have set up for this event.

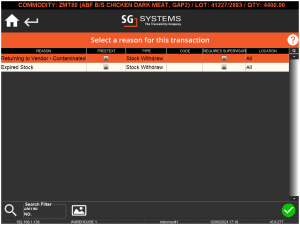

When using WMS, if the ‘Withdraw’ option is selected when managing stock:

Reasons will be prompted for once a quantity to withdraw has been input.