Master Class

Essential Product Knowledge

Summary

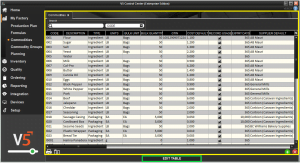

The ‘Commodities’ section of the V5 Control Center allows customers to create and configure the various ingredients and other commodities that will be used by the system for production. More information on creating commodities in V5 Traceability can be found here.

Control Center Overview

The ‘Commodities’ section is found under the ‘My Factory’ header of Control Center.

This section has 1 main panel:

- Main (yellow) panel: Where commodities can be entered into the system and subsequently edited and configured.

- Below the bottom panel we have the ‘Edit Table’ button (green) which, when pushed, allows us to edit the data in this section. This is to prevent accidental editing of this page. We can hit the button again to ‘Stop Editing’ this page once our edits have been made. This option is only available if the logged in operator has been granted sufficient privileges.

Column Help – Main Panel – Categorized View

Code

A custom commodity code can be created here. This must be unique. If entering a code which has been entered previously and deleted, the option to restore the deleted commodity will be provided with a pop up.

Description

Custom text entry to identify the commodity.

Type

Ingredient or Packaging. Ingredient (default) is used as an addition to a batch or product. Packaging is used in a Product and typically consumed at the finished product stage. Select ‘Type’ by clicking in the cell and using the pull down box.

Units

The default Unit of Measure for the commodity, usually the one it is received in. These, and other units of measure that the system uses, can be set up in ‘Units’.

Image

Allows for an image to be uploaded to represent the commodity. This will then be displayed on the terminal when the commodity is about to be used, this can aid the operator in ensuring they are using the correct commodity. Click in this column to open a dialog box where you can load an image from your computer. SG Systems would recommend a maximum image resolution of 450×450.

Physical Width

Defines the width of the commodity.

Physical Height

Defines the height of the commodity.

Physical Depth

Defines the depth of the commodity. These dimensions are used in conjunction with the dimensions of stock locations to prevent these locations from becoming overcrowded.

Datafield 1-7

Custom fields that can be used to print additional commodity information to labels.

Specific Base Conversion

Redundant field, should not be used. This has been replaced by explicit unit conversion.

Record Usage

When checked, the commodity lot number will be recorded at each handling point, allowing its movements and usage to be traced by the system for reporting purposes. When unchecked, the commodity lot number will not be prompted for or recorded at these handling points. For example, a commodity like water which does not have a lot number will not require it’s usage or lot recorded.

Expiry Days

The amount of time (in days) it takes the commodity to expire once received. This value can be overridden at the receiving stage if the particular expiry date of a supplier lot number is known and different to the default.

Expiry Method

Bespoke expiry calculation, please leave as ‘Standard’ unless SG support representative requests otherwise

Expiry Mask

Same as Expiry Method above.

Requires Expiry Change

Enabling this setting triggers an expiry date change if the commodity is moved between locations. Useful for commodities where a container needs to be opened in order to use it.

Bulk Units

The unit that the commodity is consumed in when receiving and undertaking bulk production. such as bags. Again these can be set up in ‘Units‘.

Bulk Quantity

The weight of the bulk unit of the commodity. If we use the example of bags above and set this at 50lbs, then 50lb bags will be able to be received by the system and used in bulk production.

Cleardown Threshold

If the on-hand quantity of a lot of the commodity falls below this number then the system will ask the operator whether they wish to cleardown this lot, i.e. set the on-hand value of the lot to 0.

Warning Level

Used on the stock reports, when on-hand levels drop below this level the value will be highlighted in red.

Containerized

With this option checked, the commodity will be booked into ‘containers’ upon arrival, each with its own serial number.

Palletized

With this option checked, the commodity will be booked onto ‘pallets’ upon arriving. Labels can then be printed for these pallets at the end of the PO process in WMS. Upon receipt, the system will generate a LPN (Licence plate number) or SSCC. It will also split goods down on receipt by ‘bulk count’.

Withdraw Threshold

Bespoke setting to limit the amount of stock that can be withdrawn for this commodity. Please do not enter a value in this column unless instructed to do so by SG support.

Neg Lot Change Allowance

How far below zero in a lot you are allowed to consume in production before a lot change is forced by the system.

Exempt From Initialization

Exempts this commodity from being either returned or zeroed during the ‘Initialize Inventory‘ process in WMS.

Adjustment Tolerance

The scale tolerance that will be used whenever a quantity of a commodity is adjusted.

Max Number of Pallets

The maximum number of pallets of the commodity that can be held in stock.

Default Low Tol

The default lower tolerance of the commodity permitted in a weigh step in formula production. The system will default to this value if none is entered against it as a formula step in ‘Formulas’.

Default High Tol

The default upper tolerance of the commodity permitted in a weigh step in formula production. The system will default to this value if none is entered against it as a formula step.

Batch Container

The default container that this commodity is produced into. As above, this must set up as a ‘container’.

Bulk Platform

This can be used to define a chute or silo name for the dispensing of bulk ingredients. To enable communication between the terminal and the automatic dispenser please contact SG support.

Product Of

Allows the user to define if this commodity is produced from another commodity, rather than purchased, i.e. adding water to dried yeast and then using this in a formula. Can also be used to allow for a transformation from one item to another. Only used in small label packaging ICM system.

GTIN

Enter in a 13-digit GTIN (Global Trade Item Number) and the 14th ‘check digit’ will be automatically calculated. Mainly used for Products instead of Batches and used as a label field to populate a finished product barcode.

Cost Default

The standard cost of the commodity, calculated per unit. Cost default is only used when lot specific costs are not captured alongside a supplier purchase order.

Supplier Default

The default supplier for this commodity. Can be set up in ‘Suppliers’. This can be helpful for quickly setting up repeated purchase orders of the same commodity.

Quantity Default

The default quantity to be received in orders of this commodity. Useful for when the same quantity of a commodity is regularly received.

Location Default

Can be used to set the default stock location that the commodity is received into. Useful if a commodity is received at the same location each time.

Receipt Container

The default container that this commodity is received into. Must be set as a ‘container’ type in ‘Containers’.

Purchasing Notes

The default ‘Notes’ that will appear next to a commodity when ordering in ‘Purchase Orders’.

Unit Display Mode

When ordering this commodity via ‘Purchase Orders’, this value will either let orders be processed in different Units of Measurement (when set to ‘All’) or just the Units of Measurement specified in the ‘Units’ field above (when set to ‘Specific’).

Pack Qty

How many items per pack when it comes to selling the commodity in ‘Sales Orders‘, if sales denomination is set to type PACK. This is mostly redundant.

Skip Supplier Batch

Enabling this skips the entry of a supplier batch number when receiving the item in WMS.

Tax Code

The tax code of the commodity.

MOQ

Minimum order quantity – Filling this column with a quantity (in the commodity’s base UoM) will prevent purchase orders being raised for this commodity that contain less than this quantity.

Column Help – Main Panel – List View

Code

A custom commodity code can be created here. This must be unique. If entering a code which has been entered previously and deleted, the option to restore the deleted commodity will be provided with a pop up.

Description

Custom text entry to identify the commodity.

Type

Ingredient or Packaging. Ingredient (default) is used as an addition to a batch or product. Packaging is used in a Product and typically consumed at the finished product stage. Select ‘Type’ by clicking in the cell and using the pull down box.

Units

The Unit of Measure that the commodity is received in. These can be set up in ‘Units’. If you intend to weigh the commodities as part of your production process, use either Pounds or Kilos (depending on what your scales are calibrated)

Bulk Units

The unit that the commodity is consumed in when undertaking bulk production e.g. bags. Again these can be set up in ‘Units‘.

Bulk Quantity

The weight of the bulk unit of the commodity. If we use the example of bags above and set this at 50lbs, then 50lb bags will be able to be used in bulk production.

GTIN

Enter in a 13-digit GTIN (Global Trade Item Number) and the 14th ‘check digit’ will be automatically calculated. Mainly used for Products instead of Batches and used as a label field to populate a finished product barcode.

Cost Default

The standard cost of the commodity, calculated per unit. Cost default is only used when lot specific costs are not captured alongside a supplier purchase order.

Record Usage

When checked, the commodity lot number will be recorded at each handling point. When unchecked, the commodity lot number will not be prompted for or recorded at these handling points. For example, a commodity like water which does not have a lot number will not require it’s usage or lot recorded.

Expiry Days

The amount of time (in days) it takes the commodity to expire once received. This value can be overridden at the receiving stage if the particular expiry date of a supplier lot number is known and different to the default.

Supplier Default

The default supplier for this commodity. Can be set up in ‘Suppliers’. This can be helpful for quickly setting up repeated purchase orders of the same commodity.

Quantity Default

The default quantity to be received in orders of this commodity. Useful for when the same quantity of a commodity is regularly received.

Location Default

The default location where this commodity will be stored. Useful if a commodity is received into the same location each time.

Default Low Tol

The default lower tolerance of the commodity permitted in a weigh step in formula production. The system will default to this value if none is entered against it as a formula step in ‘Formulas’.

Default High Tol

The default upper tolerance of the commodity permitted in a weigh step in formula production. The system will default to this value if none is entered against it as a formula step.

Receipt Container

The default container that this commodity is received into. Must be set as a ‘container’ type in ‘Containers’.

Batch Container

The default container that this commodity is produced into. As above, this must set up as a ‘container’.

Cleardown Threshold

If the on-hand quantity of a lot of the commodity falls below this number then the system will ask the operator whether they wish to cleardown this lot, i.e. set the on-hand value of the lot to 0.

Purchasing Notes

The default ‘Notes’ that will appear next to a commodity when ordering in ‘Purchase Orders’.

Specific Base Conversion

Redundant field, should not be used. This has been replaced by explicit unit conversion.

Bulk Platform

This can be used to define a chute or silo name for the dispensing of bulk ingredients. To enable communication between the terminal and the automatic dispenser please contact SG support.

Warning Level

Used on the stock reports, when on-hand levels drop below this level the value will be highlighted in red.

Image

Allows for an image to be uploaded to represent the commodity. This will then be displayed on the terminal when the commodity is about to be used, this can aid the operator in ensuring they are using the correct commodity. Click in this column to open a dialog box where you can load an image from your computer. SG Systems would recommend a maximum image resolution of 450×450.

Unit Display Mode

When ordering this commodity via ‘Purchase Orders’, this value will either let orders be processed in different Units of Measurement (when set to ‘All’) or just the Units of Measurement specified in the ‘Units’ field above (when set to ‘Specific’).

Expiry Method

Bespoke expiry calculation, please leave as ‘Standard’ unless SG support representative requests otherwise

Expiry Mask

Same as Expiry Method above.

Containerized

With this option checked, the commodity will be booked into ‘containers’ upon arrival, each with its own serial number.

Withdraw Threshold

Bespoke setting to limit the amount of stock that can be withdrawn for this commodity. Please do not enter a value in this column unless instructed to do so by SG support.

Physical Width

Defines the width of the commodity.

Physical Height

Defines the height of the commodity.

Physical Depth

Defines the depth of the commodity. These dimensions are used in conjunction with the dimensions of stock locations to prevent these locations from becoming overcrowded.

Product Of

Allows the user to define if this commodity is produced from another commodity, rather than purchased, i.e. adding water to dried yeast and then using this in a formula. Can also be used to allow for a transformation from one item to another. Only used in small label packaging ICM system.

Pack Qty

How many items per pack when it comes to selling the commodity in ‘Sales Orders‘, if sales denomination is set to type PACK. This is mostly redundant.

Palletized

With this option checked, the commodity will be booked onto ‘pallets’ upon arriving. Labels can then be printed for these pallets at the end of the PO process in WMS. Upon receipt, the system will generate a LPN (Licence plate number) or SSCC. It will also split goods down on receipt by ‘bulk count’.

Datafield 1-7

Custom fields that can be used to print additional information to labels.

Neg Lot Change Allowance

How far below zero in a lot you are allowed to go before a lot change is forced by the system.

Exempt From Initialization

Exempts this commodity from being either returned or zeroed during the ‘Initialize Inventory‘ process in WMS.

Adjustment Tolerance

The scale tolerance that will be used whenever a quantity of a commodity is adjusted.

Skip Supplier Batch

Enabling this skips the entry of a supplier batch number when receiving the item in WMS.

Tax Code

The tax code of the commodity.

Max Number of Pallets

The maximum number of pallets of the commodity that can be held in stock.

MOQ

Minimum order quantity – Filling this column with a quantity (in the commodity’s base UoM) will prevent purchase orders being raised for this commodity that contain less than this quantity.

Requires Expiry Change

Enabling this setting triggers an expiry date change if the commodity is moved between locations. Useful for commodities where a container needs to be opened in order to use it.