Operators

Module Guide - A Deeper Dive!

Introduction

Operator control is an essential part of any manufacturing operation. Employees are individual in their skill sets and system knowledge. Therefore V5 Traceability contains an assortment of Operator privileges to help customize the system to the needs of the business.

Default Supervisor, Partial Supervisor, and Operator settings allow a preconfigured set of permissions to quickly assign a default role to employees with primarily shop floor responsibility.

Alongside default production roles, V5 Traceability allows individual customization for specific functions, either in the back office or production environments. This guide explains the roles in detail to assist management in assigning privileges.

Operators can select their own system highlight colors for rapid login recognition. Operator language select converts the system to the operators preferred written language.

Table of Contents

1. Operator Setup

When setting up a new operator in Control Center, we can do this in three different ways:

- We can set up an operator individually.

- We can set up an operator by recalling a template that has a preset configuration

- We can set up an operator individually and then copy/paste another operator’s permissions.

1.1. Individual Operator Setup

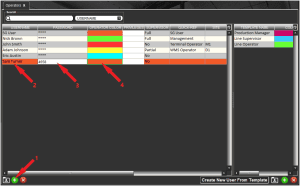

To set up a new user/operator in Control Center we first need to add a new line in the left panel by using the green ‘+’ icon at the bottom left of the screen (1). Once this is done, we can begin to enter data for our new operator. In this case we will create a Terminal operator called ‘Sam Turner’. Once we enter the name of our new user (2), we then need to create a PIN for them. This will be displayed while being entered into this cell (3).

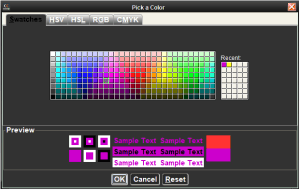

The ‘Operator Color’ should then be selected (4). This is highly customizable and can be selected either through preset swatches or by creating a custom color via the HSV (Hue Saturation Value), HSL (Hue Saturation Lightness), RGB (Red Green Blue) or CMYK (Cyan Magneta Yellow Black) tabs.

As we are browsing through different colors, we can see a preview of how this will look to the operator across the various V5 applications. The selected color will then be used to accent the various V5 Traceability apps as this operator uses them.

We can then assign a supervisor role as well as customizing the privileges that the operator should have within the system.

1.2. Creating From a Template

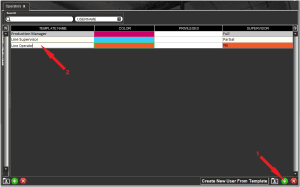

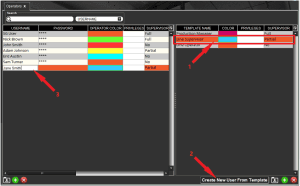

We can also create a new operator from a preset template. We can create these templates in the right panel of the ‘Operators’ window. If we use the green ‘+’ in the bottom right corner of the window (1) we can add a new line to this panel. We can name this whatever we like to best suit the description of the role template we are creating, in this case ‘Line Operator’ (2).

We can then assign a color, system privileges and a supervisor role to this template.

We can then, with a template selected in the right panel (1), use the ‘Create New User From Template’ button in the lower right corner of the screen (2), to add a new user to the left panel with these preset options. We can then add a name and PIN number for this new user to complete their setup.

We would not need to look at the supervisor or privileges settings this time as they will have been sourced from the template, making the setup of multiple users for different roles quick and easy.

1.3. Copying User Permissions

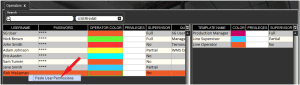

Finally, we can, if we have the correct privileges set for Control Center (see below), copy and paste permissions from one operator to another.

We can do this in the left panel by simply right clicking an operator and selecting ‘Copy User Permissions’:

And then right clicking a newly created (or pre existing) operator and pasting those permissions:

2. Privileges

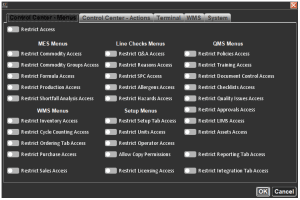

We will then have to set the privileges for this operator. This can be broken down into 4 main sections:

The privileges set here apply to the Control Center application only and determine operator access to the various menus within the application.

Restrict Access

With this checked the operator will be unable to log in to Control Center.

MES Menus

Restrict Commodity Access

Prevents access to the ‘Commodities’ window when checked.

Restrict Commodity Groups Access

Prevents access to the ‘Commodity Groups‘ window when checked.

Restrict Formula Access

Prevents access to the ‘Formulas’ window when checked.

Restrict Production Access

Prevents access to the ‘Production Plan’ window when checked.

Restrict Shortfall Analysis (Planning) Access

This restricts an operator’s access to the ‘Sortfall Analysis’ (‘Planning‘) page of Control Center.

WMS Menus

Restrict Inventory Access

Prevents access to the ‘Manage Inventory’ window when checked.

Restrict Cycle Counting Access

This restricts an operator’s access to the ‘Cycle Counting‘ page of Control Center.

Restrict Ordering Tab Access

This restricts an operator’s access to the entire ‘Ordering’ section of Control Center.

Restrict Purchase Access

Prevents access to the ‘Purchase Orders’ window when checked.

Restrict Sales Access

Prevents access to the ‘Sales Orders’ window when checked.

Line Checks Menus

Restrict Q&A Access

Prevents access to the ‘Q&A’ window when checked.

Restrict Reasons Access

This restricts an operator’s access to the ‘Reasons‘ page of Control Center.

Restrict SPC Access

This restricts an operator’s access to the ‘SPC‘ page of Control Center.

Restrict Allergens Access

This restricts an operator’s access to the ‘Allergens‘ page of Control Center.

Restrict Hazards Access

This restricts an operator’s access to the ‘Hazards‘ page of Control Center.

Setup Menus

Restrict Setup Tab Access

This restricts an operator’s access to the entire ‘Setup’ section of Control Center.

Restrict Units Access

Prevents access to the ‘Units’ window when checked.

Restrict Operator Access

Prevents access to the ‘Operators’ window when checked.

Allow Copy Permissions

If checked this allows the operator to copy the permissions of another operator and paste them to another. This is done by right clicking the operator line in ‘Operators’.

Restrict Licensing Access

This restricts an operator’s access to the entire ‘Licensing/Applications’ section (previously ‘Devices’) of Control Center.

QMS Menus

Restrict Policies Access

This restricts an operator’s access to the entire ‘Policies’ section of Control Center.

Restrict Training Access

This restricts an operator’s access to the entire ‘Training’ section of Control Center.

Restrict Document Control Access

This restricts an operator’s access to the entire ‘Document Control’ section of Control Center.

Restrict Checklists Access

This restricts an operator’s access to the entire ‘Checklists’ section of Control Center.

Restrict Quality Issues Access

This restricts an operator’s access to the entire ‘Quality Issues’ section of Control Center.

Restrict Approvals Access

This restricts an operator’s access to the entire ‘Approvals’ section of Control Center.

Restrict LIMS Access

This restricts an operator’s access to the entire ‘LIMS’ section of Control Center.

Restrict Assets Access

This restricts an operator’s access to the entire ‘Assets’ section of Control Center.

Restrict Reporting Tab Access

This restricts an operator’s access to the entire ‘Reporting’ section of Control Center.

Restrict Integration Tab Access

This restricts an operator’s access to the entire ‘Integration’ section of Control Center.

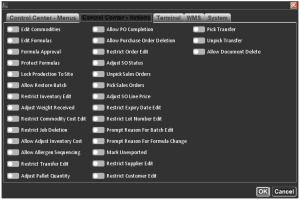

The privileges set here apply to the Control Center application only and determine what actions the user can perform while using the software.

Edit Commodities

If checked this allows the operator to make changes in the ‘Commodities’ window.

Edit Formulas

If checked then the operator will be able to create/edit/delete formulas.

Formula Approval

Allows the operator to approve formulas with the ‘Awaiting Approval’ status. With the new ‘Approval Workflows’ module this allows users to approve in ‘Approval Workflows’ window. Recommenced for trusted users.

Protect Formulas

If checked this allows the operator to view formulas with the protected status. Recommenced for trusted users.

Lock Production to Site

If checked, the operator will only see jobs, formulas and purchase orders that are assigned to the site they are working on. The site for each instance of Control Center can be set as a configuration setting. Please contact SG support for assistance setting this up.

Allow Restore Batch

Allows the operator to restore an aborted batch in the ‘Batch Log‘ by right clicking them.

Restrict Inventory Edit

If checked this restricts the operator’s ability to edit the ‘On Hand’ value for non-palletized inventory in ‘Manage Inventory‘.

Adjust Weight Received

If checked this allows the operator to edit the ‘Weight Received’ column in ‘Manage Inventory‘.

Restrict Commodity Cost Edit

This restricts an operator’s ability to change the cost (per unit) of raw materials in the ‘Commodities‘ window.

Restrict Job Deletion

This restricts an operator’s ability to delete jobs from the ‘Production Plan‘.

Allow Adjust Inventory Cost Edit

Allows the operator to adjust the ‘cost’ of individual lots in ‘Manage Inventory‘.

Allow Allergen Sequencing

Checking this box allows the operator to use the allergen sequencer in the ‘Production Plan’.

Restrict Transfer Edit

Restricts the operator’s ability to edit Transfers.

Adjust Pallet Quantity

Checking this box allows the operator to adjust the quantity of palletized items in ‘Manage Inventory‘.

Allow PO Completion

Allows an operator to force complete purchase orders from Control Center, regardless of their status.

Allow Purchase Order Deletion

Allows the operator to delete Purchase Orders if checked.

Restrict Order Edit

Restricts the operator from editing Purchase Orders.

Adjust SO Status

If checked the operator will be allowed to change the status of Sales Orders to Created/Scheduled/Awaiting Verification/Awaiting Shipping/Shipped.

Unpick Sales Orders

If checked this allows the operator to ‘unpick’ items from completed sales orders. This is done by right-clicking the relevant lot in the ‘Sales Orders’ window.

Pick Sales Orders

If checked this allows the operator to pick stock for sales orders directly from Control Center. Dispatch still requires WMS.

Adjust SO Line Price

Allows the user to adjust the line item price for Sales Orders.

Restrict Expiry Date Edit

This restricts an operator’s ability to change expiry dates in the ‘Inventory‘ window.

Restrict Lot Number Edit

This restricts an operator’s ability to change lot numbers in the ‘Inventory’ window.

Prompt Reason for Batch Edit

Prompts for a reason when adding and editing batches in the ‘Batch View‘ window.

Prompt Reason for Formula Change

If checked this will prompt the operator for a reason when making changes when editing a formula.

Mark Unexported

If checked this allows the operator to mark Purchase Orders as unexported, allowing them to be exported again from the V5 API.

Restrict Supplier Edit

Restricts the operator from being able to edit ‘Supplier‘ information.

Restrict Customer Edit

Restricts the operator from being able to edit ‘Customer‘ information.

Pick Transfer

If checked this allows the operator to pick stock for transfer orders directly from Control Center. Dispatch still requires WMS.

Unpick Transfer

If checked this allows the operator to ‘unpick’ items from completed sales orders. This is done by right-clicking the relevant lot in the ‘Transfers’ window.

Allow Document Delete

Allows the user to delete documents from the ‘Document Repository’.

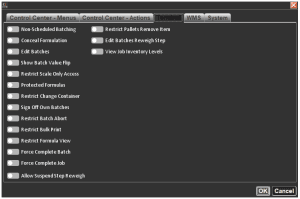

The privileges set here apply to the Terminal application only.

Non-Scheduled Batching

If selected this will allow the operator to undertake non-scheduled batching from the ‘All Formulas’ window in Terminal.

Conceal Formulation

If this is checked then, while batching, the weigh screen will not display the target weight for ingredients/commodities. Instead, this just show the weighing dial to show the operator how close they are to the target weight. This is useful for formulas that need to be kept secret.

Edit Batches

If checked then the operator has the ability to edit batches after they have been weighed out.

Show Batch Value Flip

If this is checked, while batching the operator can click the center of the scale to show the value of the commodities used rather than the weight.

Restrict Scale Only Access

If this is checked then the operator will be prevented from using ‘Launch Scale Only’ in the ‘Station Set Up’ window.

Protected Formulas

Checking this box will allow the operator to work on protected formulas. Whether a formula is protected or not can be set up in the ‘Formulas’ section of Control Center.

Restrict Change Container

If this box is checked the operator will not be able to use the ‘Actions -> Change Container’ option while batching.

Sign off Batches

If checked, this will allow this operator to use their credentials to sign off on batches that require it. Whether this is required can be set up in ‘Formulas’.

Restrict Batch Abort

If this is checked then the operator will not be able to abort batches that are in progress.

Restrict Bulk Print

Checking this box will prevent the operator from bulk printing labels when in production.

Restrict Formula View

Checking this will prevent the operator from using the ‘Formula’ button during batching to see the Formula steps and commodity requirements. As with ‘Conceal Formulation’ above, this is useful for formulas that need to be kept secret.

Force Complete Batch

Checking this will allow the operator to complete a batch even if all steps have not been completed.

Force Complete Job

Checking this will allow the operator to complete a job even if all batches have not been completed.

Allow Suspend Step Reweigh

Checking this will allow the operator to reweigh a suspended step without a supervisor override.

Restrict Pallets Remove Item

Checking this box prevent the operator removing items from a pallet once they have been produced onto that pallet.

Edit Batches Reweigh Step

When using bagging modes when batching, gives the ability to completely reweigh a formula step.

View Job Inventory Levels

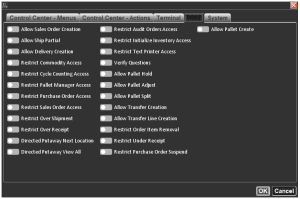

The privileges set here apply to the WMS application only.

Allow Sales Order Creation

If checked this allows the operator to both create new, and add commodities to existing, Sales Orders.

Allow Ship Partial

Checking this allows the operator to ‘Ship Partial’ on the final sales order screen.

Allow Delivery Creation

Checking this allows the operators to create Purchase Orders within WMS.

Restrict Commodity Access

Prevents the operator from accessing the ‘Commodities’ section of WMS if checked.

Restrict Cycle Counting Access

Prevents the operator from accessing the ‘Cycle Counting’ section of WMS if checked.

Restrict Pallet Manager Access

Prevents the operator from accessing the ‘Pallets’ section of WMS if checked.

Restrict Purchase Order Access

Prevents the operator from accessing the ‘Purchase Orders’ section of WMS if checked.

Restrict Sales Order Access

Prevents the operator from accessing the ‘Sales Orders’ section of WMS if checked.

Restrict Over Shipment

If checked this prevents the operator from shipping more of a commodity than is listed on a sales order.

Restrict Over Receipt

If checked this prevents the operator from receiving more of a commodity than is listed on a purchase order.

Directed Putaway Next Location

Checking this allows the operator to use the ‘Next Location’ option when moving pallets in Pallet Manager.

Directed Putaway View All

Checking this allows the operator to use the ‘View All Locations’ option when moving pallets in Pallet Manager.

Restrict Audit Orders Access

Restricts access to the ‘Manage Orders’ window when checked.

Restrict Initialize Inventory Access

Restricts access to the ‘Initialize Inventory’ window (if enabled) when checked.

Restrict Text Printer Access

Restricts access to the ‘Text Window‘ window when checked.

Verify Questions

If checked, this will allow the operator to check and verify answers given in Lab Testing.

Allow Pallet Hold

When checked this enables the operator to hold pallets in Pallet Manager.

Allow Pallet Adjust

When checked this enables the operator to make stock adjustments to pallets in Pallet Manager.

Allow Pallet Split

When checked this enables the operator to split pallet contents in Pallet Manager.

Allow Transfer Creation

When checked this enables the operator to create Transfer Orders in WMS.

Allow Transfer Creation

When checked this enables the operator to add lines to Transfer Orders in WMS.

Restrict Order Item Removal

Checking this box prevents the operator from removing line items from Sales/Purchase/Transfer Orders.

Restrict Under Receipt

Checking this box prevents the operator from under receiving Purchase Orders/Transfers.

Restrict Purchase Order Suspend

Checking this box prevents the operator suspending a Puruchase Order, essentially forcing order completion, unless other restrictions on under receipt are applied.

Allow Pallet Create

Allows the user to create new pallets using the ‘Pallet Manager’.

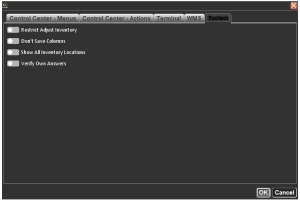

The privileges set here apply throughout the V5 environment.

Restrict Adjust Inventory

When checked this will prevent this operator from changing the quantity of stock available. This applies to both the ‘Manage Inventory’ screen in Control Center and ‘Adjust Inventory’ in WMS.

Don’t Save Columns

If checked this will prevent any customizations made to the operator’s UI by the user from being saved when they log out of any V5 application. Upon logging in again, default column views will be restored.

Show All Inventory Locations

If checked then the operator will be able to see all inventory locations, as opposed to just the location they are assigned to if it were to remain unchecked.

Verify Own Answers

If checked then the operator, if they are set as a supervisor, will be able to verify their own answers in instances where a supervisor signoff is required, such as batch signoff, or a supervisor override to abort a batch.

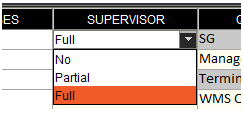

3. Supervisor

We can set a Supervisor status against each operator using the drop down menu in the ‘Supervisor’ cell.

Our 3 options break down like so:

- Full – Allows supervisor overrides to be authorized by this operator. Also allows access to full application settings of Terminal & WMS.

- Partial – Allows supervisor overrides to be authorized by this operator. Only allows access to Terminal user settings.

- No – This operator will be unable to perform supervisor overrides. Only allows access to Terminal user settings.

4. Username/Password Login Option

As well as the PIN login method, SG Systems also offer a username and password login option that can be enabled or disabled either system wide, or for specific devices.

More information on the added security features that this can provide can be found here.

4.1. IT Administrator Role

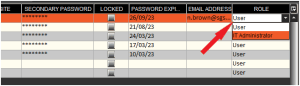

Tied to the enabling of the username and password login option is the addition of an ‘IT Administrator’ role. This can be found in the ‘Role’ column:

These roles are designed to allow personnel who are separate from the production side of the business to manage user access to the V5 Traceability system. This helps to prevent any conflicts of interest.

These two roles work as follows:

- User – Operators assigned this role will be able to access all areas of Control Center (dependent on individual privileges) except ‘Operators’.

- IT Administrator – Operators assigned this role will only be able to access ‘Operators’ (regardless of any individual privileges).

Please note that the username/password login method must be enabled to use this feature.

Contact SG Support if you would like more information on implementing this feature for your site.

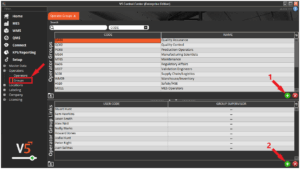

5. Operator Groups

New for v5.9, the ‘Operator Groups’ page can be found under the ‘Operators’ under the ‘Setup’ menu in Control Center.

Once here, groups can be created in the top panel (1), and once these are created and selected, operators can be added to these groups in the bottom panel (2).

As many operators as desired can be added to each group here.

Once created, these operator groups can be used within different V5 QMS modules such as ‘Approval Workflows‘ and ‘Checklists‘.